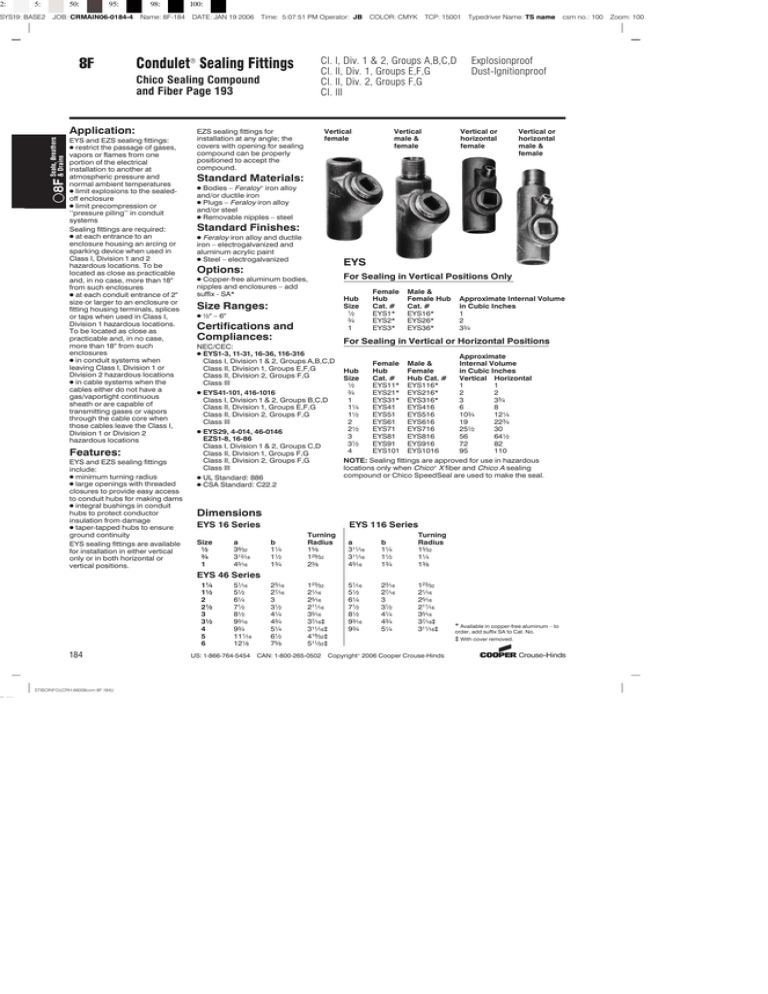

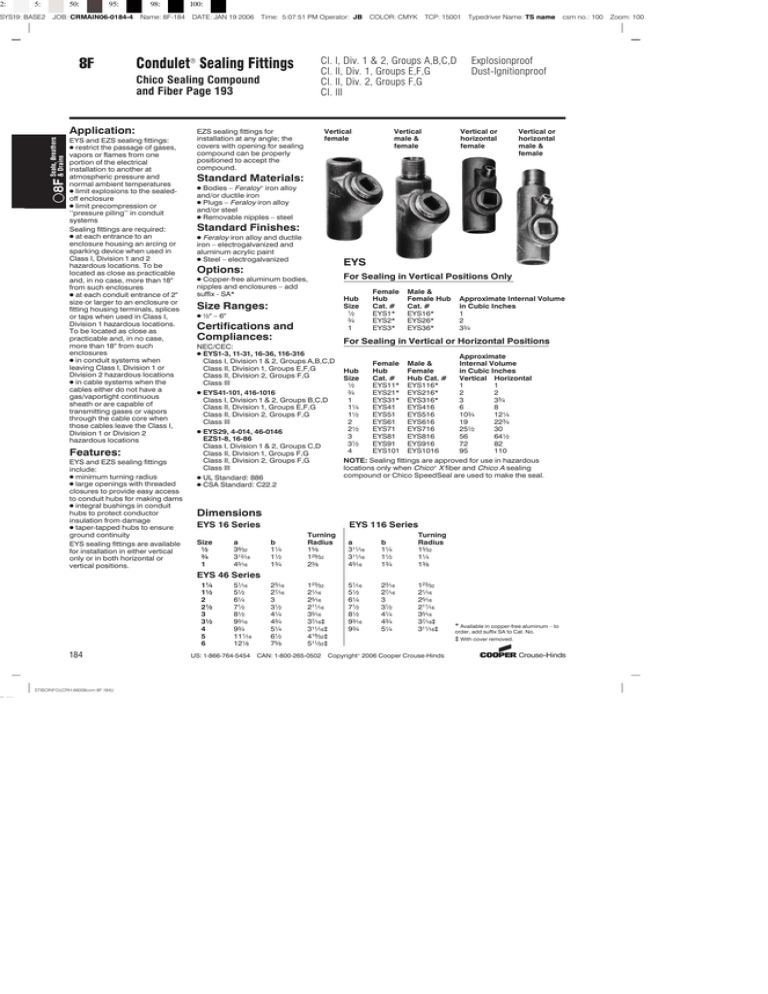

EYS series for direct coupling to the equipment, with or without interposition of tube (length not greater than the nominal diameter of the joint). Sealing fittings for vertical installation only, divided into two types such as:. One of the possible solution, as mentioned above, is the use of sealing fittings, which are subdivided into types such as: The Standards EN 60079-14 and IEC 60079-14, at paragraph 10.6.2, specify the choosing of the entry system, as shown in the following diagram. The mechanical maintenance technician has the task of keeping operating all the electrical equipment, that can be the cause of physical or material damage due to lack of controls over time, routine cleanings and compliance to all the instructions given by the manufacturer in the owner's handbook. Furthermore, he has to check the overall functionality of the system and the correct mounting and sealing of the sealing fittings. The security supervisor has the task of checking that the installer has performed all the provisions of the project in the best way and in compliance with the relevant Standards. The installer must perform in the best way,and respecting all the provisions in the plant according to EN 60079-14 and IEC 60079-14 Standards, as designed and planned by the designer. The designer has the task of size properly the sealing fittings, evaluating, in addition to all the primary variables such as the size of the cable for current flow, voltage drop, type of cable, temperature class commensurate to enclosure or end user temperatures, even the correct filling of the sealing fittings, respecting the provisions of EN 6 Standards in paragraph 9.4, taking care to "fill" the joint up to a maximum of 40% of its section (if included 3 or more conductors in the same fitting).

The difference between the functions of "Designer", "Installer", " Safety supervisor " and "Maintenance Technician" is: Furthermore, it can cause economic damage for the loss of production in case of functional failure and out of order of the equipment. This carelessness and failure to comply with the manufacturer's requirements will invalidate every product guarantee (and this would be the lesser of evils), involving a huge risk to the safety and functionality of the system, with possible health risks and damage to operators. This is due to the superficiality of the operators in charge of assembly operations, safety supervision and testing.

In electrical equipment in which it’s necessary to have a physical separation for the limitation of the flame passage, such as petrochemical, oil and gas, chemical industrial plants and, generally, in places with a potentially explosive atmosphere and the possible presence of gas and dust, must be used specific limitation devices such as sealed cable glands or sealing fittings.ĭuring the inspection operations of facilities, the sealing fittings have been found too many times not installed as indicated by the manufacturer or not filled with the specific sealant material provided with the sealing fittings or even missing between two adjacent boxes.

0 kommentar(er)

0 kommentar(er)